• slickandhandy.com - our online store,

• allegro - our offer on polish local marketplace,

• etsy - our offer on international marketplace.

Our specialty is mechanical design. From electronic casings up to military grade servodrives with manual override. Unusual openwork frames easy to produce but sophisticated enough to amaze your clients. Plastic components and assemblies modeled with 3d free-form surfaces, built from the bottom up with injection molding technology in mind and designed to show elegance. Finite Elements Analysis and FEM optimized shape to best exploit available materials.

We can exploit to the maximum such technologies like machining, turning - both CNC and traditional, laser cutting, water jet, rapid prototyping and rapid manufacturing technologies known as 3d printing.

Basic knowledge of electrical and electronics engineering allows us to make good contact with your electrical and electronics designers.

We make drawings, geometry files for cnc workshops, renderings, product photos and drawings for marketing.

Mainly we use Solidworks software.

For the Exofin Sp. z o.o., Gdynia, we've designed skeleton for their folding fins.

Exofin has created and patented whole new concept for diving fins. This innovative product revolutionizes diving, especially by special forces.

At MSPO Kielce (The International Defence Industry Exhibition in Kielce, Poland) which took place in the early September 2014, Exofin's folding fins were awarded with Targi Kielce Special Medal. We're proud we could help the Exofin in achieving such a success.

For the Exofin Sp. z o.o., Gdynia, we've designed skeleton for their folding fins.

Exofin has created and patented whole new concept for diving fins. This innovative product revolutionizes diving, especially by special forces.

At MSPO Kielce (The International Defence Industry Exhibition in Kielce, Poland) which took place in the early September 2014, Exofin's folding fins were awarded with Targi Kielce Special Medal. We're proud we could help the Exofin in achieving such a success.

Ensolver’s owner (Miroslaw Baszun, hereinafter MB) as the principle mechanical design engineer at AREX Sp. z o.o., Poland, had oportunity to contribute to polish defence industry. Below is a bunch of examples.

The task included servomotors adaptation, mechanical design of operating panel (also graphics design), modular system of casings for fast exchange faulty units, and very successful military grade joystick used later in most of defense projects. For that joystick MB created tools for manufacturing complicated silicon rubber cover using quite simple mold without need of injection molding press, what made whole process very cheap at low scale production.

You can watch entire product at the video below:

In this case MB’s work included design of servomechanisms, extended multitrack rotating joint and casing for electronics.

MB’s works included design of housing, graphics design, design of water-proof and low temperature capable buttons as well as the technology for manufacturing them. Panel complies with military grade EMC (Electro-Magnetic Compatibility) requirement, as well as other military requirements. This control panel is widely used in other military projects.

That task included magnetically shielded servomechanisms and casings for electronics.

MB’s work included design of the turret’s electro-drives, automatic ammo magazine, all drives for ammo delivery system and targeting sight (precise driven platform for electro-optical systems). Most of electro-drives have manual override, ammo magazine contain lightweight openwork frame. The sight has completely backlash-compensated mechanism. Other engineers under MB’s command created all modular electronics casings.

You can watch entire product at the video below:

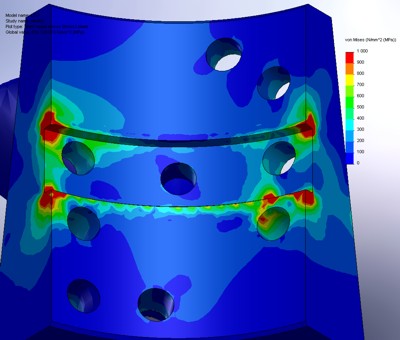

Our designs often require precise stress analysis for complex shape. Such problems we solve using Finite Element Method. Using proper software we can optimize designed mechanical components and structure or just check obtained factor of safety. Super light openwork frame, a gear's non-typical bushing or integrated into structure plastic spring with "programmed" deformation are impossible or extremely hard to calculate using legacy methods. FEM makes it possible.

Our designs often require precise stress analysis for complex shape. Such problems we solve using Finite Element Method. Using proper software we can optimize designed mechanical components and structure or just check obtained factor of safety. Super light openwork frame, a gear's non-typical bushing or integrated into structure plastic spring with "programmed" deformation are impossible or extremely hard to calculate using legacy methods. FEM makes it possible.

We also make FEM analysis for our clients, such as a ship's propeller's blade fixing evaluation for CTO Gdansk.

For Medicalgorithmics S.A., Poland, we've designed plastic housings for their medical products. We developed plastic parts based on our industrial design as well as on the basis on customer’s delivered design of shape. Some parts we’ve optimized using FEM and we provided close support for toolmakers workshop.

Our latest product is the Pocket ECG.

Many of our designs required creating plastic components. That included electronic casings, helical cable rails, elastomer protectors for mechanisms running at very low temperatures, insulators, vibro-isolators, waterproof buttons, gaskets, and multitrack gas valve/separator for chemical analyser. We developed parts designated for mass production injection molding, short run and yet economical injection molding, machining and Selective Laser Sintering. We utilized such materials like PEI, polycarbonate, polyamide, POM, ABS, PP, teflon, silicone rubber and different composites.

My name is Mirosław Baszun (pron.: Meerosuav Bashoon). I live and work in Gdynia, Poland. I am a business owner of Ensolver.

My work experience comes from 26 years of designing mechanics for industrial automation, medical equipment and first of all - defence. I've been a draftsman, designer, team leader, principle design engineer. Now I'm an entrepreneur, making my own way into industry. Non-standard projects is what I am not afraid of. Challenges are what drives me. Others says: "it's impossible", then I show: "it works".

Privately I'm a husband and father. My credo in life is making my words fully worth their importance.